How to understand Motorcycle Chains, Wear and Maintenance...

:: Mechanical Forum :: How To's

Page 1 of 1

How to understand Motorcycle Chains, Wear and Maintenance...

How to understand Motorcycle Chains, Wear and Maintenance...

I first have to thank a Dear friend, CyberPoet, for such great infromation!

For most current motorcycles, the power from the engine and transmission is delivered to the rear wheel via a drive chain, although some models use driveshafts (many BMW's and some Honda's come to mind), and others use belts instead of chains (some Harleys, some Hondas, etc.).

While it can be argued that shafts are better because they don't require nearly as much maintenance, shaft drives do have a penalty in both total weight and (often more importantly) unsprung weight. Similarly, it can be argued that belts are better than chains, but the reality is that for an equal amount of torque to be transmitted, a chain can be both much narrower and generally be more reliable at transmitting that power. Either way, your particular bike manufacturer made the decision at the design stage as to which would be most suitable to the purposes your bike is intended for, and in most cases that means a chain.

--------------------------------------------------------------------------------

TYPES OF MODERN CHAINS:

Motorcycle chains are broken down by a number of simple criteria: width, length, and roller-support lubrication design. Standard widths are 520 and 530. Standard lengths are counted by the number of links in the chain -- 110/112/114/116/118/120 are standard link counts, and you can obtain chains up to 140 links from most manufacturers. As for the roller-support lubrication method, that gets a bit more complicated...

Cut away of a DID O-ring Chain:

NOTE: These are some of many possible designs, and some sealed-ring designs place the seal between the pin and the roller or between the pin and the inner sideplate rather than between the inner and outer sideplates. Furthermore, some do not have a roller-bearing as a part of the support mechanism, but use a bushing or the pressure on the lubricant itself as the roller support structure.

Old time chains were simply open-ended roller bearings and you had to lubricate them exceedingly well to keep them from wearing the bearings down too fast (usually by immersing them in oil every several hundred miles). Newer chains employ a sealed lubricant inside the chain roller mechanism, and then maintain the seal on the lubricant reserve using a rubber (usually a synthetic rubber-substitute like NBR) sealing ring of some sort. These chains are broken down by the shape of the seal they use to seal in the lubricant. The typical method is a sealant ring shaped like a big "O", and those kinds of chains are called o-ring chains. Alternatively, some manufacturers have designed sealant rings shaped like an "X", a "W", a "Z" and a variety of other shapes to help promote a long seal life (and avoid possible patent infringement upon others).

Please note that simply because you are using a sealed-link chain does not mean you do not need to lubricate it. Lube your chains!

--------------------------------------------------------------------------------

UNDERSTANDING FAILURE:

Modern sealed-ring chains fail for only three primary reasons:

Physical Interference:

Something sizeable gets trapped between the chain and the sprocket after having been picked up, such as a wire coat hanger. Other than picking a good path and trying to avoid road debris, there isn't much you can do about this. Yank your clutch in as fast as possible, kill the engine and coast to safe stopping place (if the wheel is still turning -- otherwise try to keep it upright as you skid to a safe place -- feet out!).

Loss of Seal Integrity:

The seal(s) retaining the lubrication for one or more rollers fails. Typical causes include: abrasion (such as sand rubbing between the seal and one of the plates); friction (heat generated by inadequate lubrication external to the seals as the plates rub against them); weathering and age (seal dries out, cracks), or other stresses (such as chemical exposure to naphtha or other harsh chemicals). The primary way to keep this kind of failure from occurring is to keep the chain (and thus the seals) free of sand, dirt and other contaminants via regular cleaning, and to keep it lubricated appropriately externally as well (to minimize the friction at the seal/plate interface, and to help keep the seals in good shape).

Although it is also possible for the sealed lubricant to leak out at another place (such as if the roller surface detaches from the inner plate), this kind of failure is much rarer.

Roller-to-Roller Distance Elongation:

Sometimes called sideplate elongation, which is usually technically be incorrect, depending on the circumstances.

Over time, the repeated pulling on the chain and overly tight chain adjustments causes the chain's subcomponents to physically elongate, and the distance between any two roller surfaces increases. Unfortunately, the distance between teeth on the sprocket doesn't elongate the same way, and the result is that only one roller is taking the majority of the force from a sprocket at any given time, instead of sharing it equally among the rollers in contact at that instant. This causes the chain to elongate and to wear at an even higher rate, and causes the sprocket teeth to start wearing unevenly (forming a wave pattern). Over-tightening the chain tension is usually part of the culprit. This form of failure is the most common form of age/wear related failure, and can often be tied into prior seal integrity failures.

To test for this kind of elongation, attempt to pull the chain away from the rear sprocket at the back center. If the chain can be lifted to the height of the top of the sprocket teeth on any brand/model, then it is elongated enough to need replacement as soon as feasible and is causing undue wear. For most street-oriented motorcycles, replacement limit is around 1.5mm of play when measured like this (i.e. - being able to pull the chain 1.5mm off the rear center of the rear sprocket).

--------------------------------------------------------------------------------

Cutting Out Links from a Stretched Chain

Because of the roller-to-roller distance elongation issue listed above, cutting links out of a chain that has stretched too long will do you no good -- the chain will still wear just as fast, and the sprockets will get worn down at the same accelerated rate as well. Just because the chain is now physically shorter doesn't change the roller-to-roller distance.

--------------------------------------------------------------------------------

FAILURE ANALYSIS:

The picture on the right is an example of a chain that is failing at 7800 miles, although it has not reached it's elongation limit by a far shot. Specifically, the chain has the following problems:

The red color close to the seals on the exterior side-plates is the sealed bearing lubricant normally used to lubricate the rollers. The seals are leaking, so the lubricant leaks out and dries into a red powder (red coloring is common to most chain brands, but not all; it's the clay carrier that is part of the lubricant package);

If you look closely at the seals themselves, you'll notice what appears to be lengthwise grooves in them; this is caused by using too hard a bristle during cleaning, one in which the material of the bristles was harder than the materials in the seals;

The inner side-plates are not aligned evenly, meaning that the lowest link in this picture is already compromised beyond the point of failure;

The rider said he diligently cleaned & lubed his chain every 400 to 600 miles. Based on what I see, he should have cleaned less and lubed more.

WHAT TO DO:

Replace this chain immediately! Failed seals cause chains to bind and break, putting the rider at risk.

Lubricate far more often that you do -- remember, you can lube far more often than you need to clean!

Change your cleaning method to a different method and/or use a softer brush.

Seriously consider changing your lubrication -- use an oil instead of a wax. The fact that the rider was using so much force to get the chain clean indicates that the lube product was clinging too much and not releasing debris & dirt.

MAINTENANCE - Sealed-ring Chains:

There are only four things you need to do regularly maintain a modern sealed-ring chain:

Clean it of debris (sand, dirt, grime);

Lubricate the exterior (oil or wax);

Adjust it for elongation (not too tight!);

Replace it when it's too elongated or worn, or the seals start to fail.

MAINTENANCE (Minor + Major) - OLD STYLE OPEN-LINK CHAINS:

Open-Link chains require significantly more maintenance than sealed-ring chains:

MINOR MAINTENANCE (every 100 to 200 miles):

Clean it of external debris (sand, dirt, grime);

Lubricate the exterior (oil) and spray excess into the bearing links;

MAJOR MAINTENANCE (every 600 to 1200 miles):

Unmount the chain;

Dip-clean it of internal debris (use a gallon container Kerosene or WD-40, plus a brush, dip repeatedly to wash any dirt, dust, etc. out of the bearing area under each roller);

Reoil the bearings (dipping it into a vat of gear oil or a pan of heated grease works well), filling all the bearings under each roller with oil/grease;

Remount the chain;

Adjust it for elongation (not too tight!);

Replace it when it's too elongated or worn, when any of the rollers are sloppy on their carrier bearings, or when any of the roller bearings fail to turn freely even after dip-cleaning.

Cleaning:

Most manufacturers recommend cleaning your chain thoroughly every 500 to 600 miles (every 1000km) with kerosene (not gasoline, naphtha, acetone or other petroleum products that dry out seals). Although old style (non-sealed) chains really need to be physically soaked to clean them, modern sealed-ring chains can normally be cleaned in place unless they are totally trashed.

--------------------------------------------------------------------------------

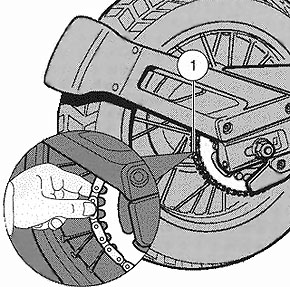

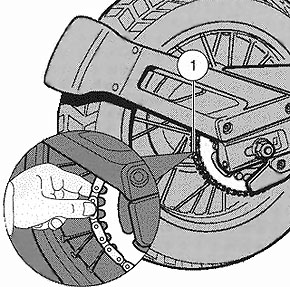

Moose Chain Scrubbers

The easiest method we have found to really clean an O-ring (sealed link) chain well is the Moose Chain Scrubber (& Sludge Away, a chemical which ships with it). The device uses the chain's motion to turn the bristles, scrubbing the chain as it passes through, and coating it with a solvent that gets rinsed off with water afterwards. 90 seconds from a gunked chain to sparkling clean.

One note: we do not recommend using your motor to turn the chain when using this chain scrubber -- turn the wheel by hand to pass the chain through, for safety reasons!

--------------------------------------------------------------------------------

Lubricating:

Your chain should be lubricated every time it is cleaned, and then some. Generally, all chain oils and chain waxes work best if the chain is physically warm (so the parts have expanded and the lubricant can penetrate better). Remember that some seals may fail quickly; the lubricant you are placing on there not only protects the seals, but also helps keep any rollers with compromised seals working until the chain gets replaced. If in doubt about what to use to clean your chain, follow the manufacturer's recommendation. Although many people swear by standard WD-40 as their chain cleaning chemical of choice, I avoid it specifically when cleaning/lubing any sealed-chains (O-ring/X-ring/W-ring) because of the 45 to 50% Stoddard Solvent in WD-40 (stoddard solvent is commonly considered dry cleaning solvent; I suspect it dries out the VOC's in the o-ring or x-ring seals). WD-40 however, is perfectly suited to cleaning old-style open-link chains.

--------------------------------------------------------------------------------

Automatic Chain Oilers

If you ride long distances, or if you are not diligent about lubricating your chain, you should take a serious look at Pro-Oiler, Scott Automatic Chain Oilers, HawkeOiler, Lubetronic, and Loobman Oiler (manual).

These devices place a single drop of oil (from a reservoir) onto your chain every twenty to sixty seconds while you are actively riding (NOTE: The Pro-Oiler is distance dependent instead of time-dependent, and the Loobman requires you squeeze the bottle), and greatly extend the chain life for a typical motorcycle by keeping the chain ideally oiled all the time.

--------------------------------------------------------------------------------

As for me, I personally spray down my chain with oil at the end of every ten mile or longer ride, thus insuring that the chain is constantly well lubricated and the seals are kept in tip-top shape. Note that it is virtually physically impossible to over-oil a chain (since excess oil will be flung off), but it is possible to over-wax a chain. I'm planning on installing a Pro-Oiler or a Lubetronic soon on my current ride, and have had Scott Oilers on past bikes.

--------------------------------------------------------------------------------

OIL OR WAX?

Note that both work, and each one has it's own benefits and drawbacks.

Wax tends to stick far firmer and longer than oil products, reducing how often you need to lubricate the chain, and providing a longer-lasting barrier against water. But wax also tends to grab onto sand and dirt and hold it really well, increasing the contamination level that can lead to excess abrasion on seals.

Oil tends to lubricate better (greater penetration), and doesn't hold onto sand & dirt contamination as well. But oil also has a tendency to fling off more readily, requiring more frequent applications. The upside to this flinging is that as the oil flings off, it takes contaminants with it, keeping the total contamination levels down.

So what should you use?

If you live in an area that has lots of sand (coastal areas, deserts), use oil.

If you are diligent about using a lubricant, use oil (keeps the contamination levels down).

If you live somewhere that doesn't get a lot of contamination, use wax.

If you are not diligent about using a lubricant, get an automatic oiler (Pro-Oiler, Scott Automatic Chain Oilers, HawkeOiler, Lubetronic, and Loobman Oiler (manual)).

If you're a starving college student, you can use automotive grease, used motor oil or vaseline in a pinch, and look at the Loobman Oiler.

--------------------------------------------------------------------------------

Adjusting:

Your chain should be checked for adjustment (slack) every time it is cleaned, and anytime you suspect it may be too slack or too tight. The golden rule is that slightly too loose a chain is infinitely safer (and less like to wear prematurely) than slightly too tight a chain. Chain adjustment methods vary between motorcycle models, and we recommend you consult your owner's manual for the proper amount of slack and the method to set the chain tension adjustment by. If you don't have an owner's manual for your motorcycle, we highly recommend you obtain one -- try searching the net, or visit your local dealership to order one. For most motorcycles that use a chain, a total flex of 1" measured halfway between the front and rear sprockets (1/2" up plus 1/2" down) is the ideal. Remember that your chain needs to have some slack so that as it spins up to full speed, it can have room for centrifugal force. The sample adjustment below is for 1998 - 2003 Katanas, as per the owner's manual, as an example:

Replacement:

Your chain will need to be replaced whenever it becomes too elongated, if the rollers are no longer turning freely, and/or whenever your sprockets are starting to wear. It should also be replaced any time you replace your sprockets with new ones, and whenever you see red powder lubricant at the links (see picture "Failure Analysis", above). A typical lifespan for a well maintained chain should be between 8,000 and 15,000 miles (12,500 to 24,000 km). A typical lifespan for a neglected chain can be under 5,000 miles and for an ignored chain is rarely over 2,500 miles. Chains using automated oilers often get 25,000 to 45,000 miles before they need to be replaced, making such oilers a good investment.

For most current motorcycles, the power from the engine and transmission is delivered to the rear wheel via a drive chain, although some models use driveshafts (many BMW's and some Honda's come to mind), and others use belts instead of chains (some Harleys, some Hondas, etc.).

While it can be argued that shafts are better because they don't require nearly as much maintenance, shaft drives do have a penalty in both total weight and (often more importantly) unsprung weight. Similarly, it can be argued that belts are better than chains, but the reality is that for an equal amount of torque to be transmitted, a chain can be both much narrower and generally be more reliable at transmitting that power. Either way, your particular bike manufacturer made the decision at the design stage as to which would be most suitable to the purposes your bike is intended for, and in most cases that means a chain.

--------------------------------------------------------------------------------

TYPES OF MODERN CHAINS:

Motorcycle chains are broken down by a number of simple criteria: width, length, and roller-support lubrication design. Standard widths are 520 and 530. Standard lengths are counted by the number of links in the chain -- 110/112/114/116/118/120 are standard link counts, and you can obtain chains up to 140 links from most manufacturers. As for the roller-support lubrication method, that gets a bit more complicated...

Cut away of a DID O-ring Chain:

NOTE: These are some of many possible designs, and some sealed-ring designs place the seal between the pin and the roller or between the pin and the inner sideplate rather than between the inner and outer sideplates. Furthermore, some do not have a roller-bearing as a part of the support mechanism, but use a bushing or the pressure on the lubricant itself as the roller support structure.

Old time chains were simply open-ended roller bearings and you had to lubricate them exceedingly well to keep them from wearing the bearings down too fast (usually by immersing them in oil every several hundred miles). Newer chains employ a sealed lubricant inside the chain roller mechanism, and then maintain the seal on the lubricant reserve using a rubber (usually a synthetic rubber-substitute like NBR) sealing ring of some sort. These chains are broken down by the shape of the seal they use to seal in the lubricant. The typical method is a sealant ring shaped like a big "O", and those kinds of chains are called o-ring chains. Alternatively, some manufacturers have designed sealant rings shaped like an "X", a "W", a "Z" and a variety of other shapes to help promote a long seal life (and avoid possible patent infringement upon others).

Please note that simply because you are using a sealed-link chain does not mean you do not need to lubricate it. Lube your chains!

--------------------------------------------------------------------------------

UNDERSTANDING FAILURE:

Modern sealed-ring chains fail for only three primary reasons:

Physical Interference:

Something sizeable gets trapped between the chain and the sprocket after having been picked up, such as a wire coat hanger. Other than picking a good path and trying to avoid road debris, there isn't much you can do about this. Yank your clutch in as fast as possible, kill the engine and coast to safe stopping place (if the wheel is still turning -- otherwise try to keep it upright as you skid to a safe place -- feet out!).

Loss of Seal Integrity:

The seal(s) retaining the lubrication for one or more rollers fails. Typical causes include: abrasion (such as sand rubbing between the seal and one of the plates); friction (heat generated by inadequate lubrication external to the seals as the plates rub against them); weathering and age (seal dries out, cracks), or other stresses (such as chemical exposure to naphtha or other harsh chemicals). The primary way to keep this kind of failure from occurring is to keep the chain (and thus the seals) free of sand, dirt and other contaminants via regular cleaning, and to keep it lubricated appropriately externally as well (to minimize the friction at the seal/plate interface, and to help keep the seals in good shape).

Although it is also possible for the sealed lubricant to leak out at another place (such as if the roller surface detaches from the inner plate), this kind of failure is much rarer.

Roller-to-Roller Distance Elongation:

Sometimes called sideplate elongation, which is usually technically be incorrect, depending on the circumstances.

Over time, the repeated pulling on the chain and overly tight chain adjustments causes the chain's subcomponents to physically elongate, and the distance between any two roller surfaces increases. Unfortunately, the distance between teeth on the sprocket doesn't elongate the same way, and the result is that only one roller is taking the majority of the force from a sprocket at any given time, instead of sharing it equally among the rollers in contact at that instant. This causes the chain to elongate and to wear at an even higher rate, and causes the sprocket teeth to start wearing unevenly (forming a wave pattern). Over-tightening the chain tension is usually part of the culprit. This form of failure is the most common form of age/wear related failure, and can often be tied into prior seal integrity failures.

To test for this kind of elongation, attempt to pull the chain away from the rear sprocket at the back center. If the chain can be lifted to the height of the top of the sprocket teeth on any brand/model, then it is elongated enough to need replacement as soon as feasible and is causing undue wear. For most street-oriented motorcycles, replacement limit is around 1.5mm of play when measured like this (i.e. - being able to pull the chain 1.5mm off the rear center of the rear sprocket).

--------------------------------------------------------------------------------

Cutting Out Links from a Stretched Chain

Because of the roller-to-roller distance elongation issue listed above, cutting links out of a chain that has stretched too long will do you no good -- the chain will still wear just as fast, and the sprockets will get worn down at the same accelerated rate as well. Just because the chain is now physically shorter doesn't change the roller-to-roller distance.

--------------------------------------------------------------------------------

FAILURE ANALYSIS:

The picture on the right is an example of a chain that is failing at 7800 miles, although it has not reached it's elongation limit by a far shot. Specifically, the chain has the following problems:

The red color close to the seals on the exterior side-plates is the sealed bearing lubricant normally used to lubricate the rollers. The seals are leaking, so the lubricant leaks out and dries into a red powder (red coloring is common to most chain brands, but not all; it's the clay carrier that is part of the lubricant package);

If you look closely at the seals themselves, you'll notice what appears to be lengthwise grooves in them; this is caused by using too hard a bristle during cleaning, one in which the material of the bristles was harder than the materials in the seals;

The inner side-plates are not aligned evenly, meaning that the lowest link in this picture is already compromised beyond the point of failure;

The rider said he diligently cleaned & lubed his chain every 400 to 600 miles. Based on what I see, he should have cleaned less and lubed more.

WHAT TO DO:

Replace this chain immediately! Failed seals cause chains to bind and break, putting the rider at risk.

Lubricate far more often that you do -- remember, you can lube far more often than you need to clean!

Change your cleaning method to a different method and/or use a softer brush.

Seriously consider changing your lubrication -- use an oil instead of a wax. The fact that the rider was using so much force to get the chain clean indicates that the lube product was clinging too much and not releasing debris & dirt.

MAINTENANCE - Sealed-ring Chains:

There are only four things you need to do regularly maintain a modern sealed-ring chain:

Clean it of debris (sand, dirt, grime);

Lubricate the exterior (oil or wax);

Adjust it for elongation (not too tight!);

Replace it when it's too elongated or worn, or the seals start to fail.

MAINTENANCE (Minor + Major) - OLD STYLE OPEN-LINK CHAINS:

Open-Link chains require significantly more maintenance than sealed-ring chains:

MINOR MAINTENANCE (every 100 to 200 miles):

Clean it of external debris (sand, dirt, grime);

Lubricate the exterior (oil) and spray excess into the bearing links;

MAJOR MAINTENANCE (every 600 to 1200 miles):

Unmount the chain;

Dip-clean it of internal debris (use a gallon container Kerosene or WD-40, plus a brush, dip repeatedly to wash any dirt, dust, etc. out of the bearing area under each roller);

Reoil the bearings (dipping it into a vat of gear oil or a pan of heated grease works well), filling all the bearings under each roller with oil/grease;

Remount the chain;

Adjust it for elongation (not too tight!);

Replace it when it's too elongated or worn, when any of the rollers are sloppy on their carrier bearings, or when any of the roller bearings fail to turn freely even after dip-cleaning.

Cleaning:

Most manufacturers recommend cleaning your chain thoroughly every 500 to 600 miles (every 1000km) with kerosene (not gasoline, naphtha, acetone or other petroleum products that dry out seals). Although old style (non-sealed) chains really need to be physically soaked to clean them, modern sealed-ring chains can normally be cleaned in place unless they are totally trashed.

--------------------------------------------------------------------------------

Moose Chain Scrubbers

The easiest method we have found to really clean an O-ring (sealed link) chain well is the Moose Chain Scrubber (& Sludge Away, a chemical which ships with it). The device uses the chain's motion to turn the bristles, scrubbing the chain as it passes through, and coating it with a solvent that gets rinsed off with water afterwards. 90 seconds from a gunked chain to sparkling clean.

One note: we do not recommend using your motor to turn the chain when using this chain scrubber -- turn the wheel by hand to pass the chain through, for safety reasons!

--------------------------------------------------------------------------------

Lubricating:

Your chain should be lubricated every time it is cleaned, and then some. Generally, all chain oils and chain waxes work best if the chain is physically warm (so the parts have expanded and the lubricant can penetrate better). Remember that some seals may fail quickly; the lubricant you are placing on there not only protects the seals, but also helps keep any rollers with compromised seals working until the chain gets replaced. If in doubt about what to use to clean your chain, follow the manufacturer's recommendation. Although many people swear by standard WD-40 as their chain cleaning chemical of choice, I avoid it specifically when cleaning/lubing any sealed-chains (O-ring/X-ring/W-ring) because of the 45 to 50% Stoddard Solvent in WD-40 (stoddard solvent is commonly considered dry cleaning solvent; I suspect it dries out the VOC's in the o-ring or x-ring seals). WD-40 however, is perfectly suited to cleaning old-style open-link chains.

--------------------------------------------------------------------------------

Automatic Chain Oilers

If you ride long distances, or if you are not diligent about lubricating your chain, you should take a serious look at Pro-Oiler, Scott Automatic Chain Oilers, HawkeOiler, Lubetronic, and Loobman Oiler (manual).

These devices place a single drop of oil (from a reservoir) onto your chain every twenty to sixty seconds while you are actively riding (NOTE: The Pro-Oiler is distance dependent instead of time-dependent, and the Loobman requires you squeeze the bottle), and greatly extend the chain life for a typical motorcycle by keeping the chain ideally oiled all the time.

--------------------------------------------------------------------------------

As for me, I personally spray down my chain with oil at the end of every ten mile or longer ride, thus insuring that the chain is constantly well lubricated and the seals are kept in tip-top shape. Note that it is virtually physically impossible to over-oil a chain (since excess oil will be flung off), but it is possible to over-wax a chain. I'm planning on installing a Pro-Oiler or a Lubetronic soon on my current ride, and have had Scott Oilers on past bikes.

--------------------------------------------------------------------------------

OIL OR WAX?

Note that both work, and each one has it's own benefits and drawbacks.

Wax tends to stick far firmer and longer than oil products, reducing how often you need to lubricate the chain, and providing a longer-lasting barrier against water. But wax also tends to grab onto sand and dirt and hold it really well, increasing the contamination level that can lead to excess abrasion on seals.

Oil tends to lubricate better (greater penetration), and doesn't hold onto sand & dirt contamination as well. But oil also has a tendency to fling off more readily, requiring more frequent applications. The upside to this flinging is that as the oil flings off, it takes contaminants with it, keeping the total contamination levels down.

So what should you use?

If you live in an area that has lots of sand (coastal areas, deserts), use oil.

If you are diligent about using a lubricant, use oil (keeps the contamination levels down).

If you live somewhere that doesn't get a lot of contamination, use wax.

If you are not diligent about using a lubricant, get an automatic oiler (Pro-Oiler, Scott Automatic Chain Oilers, HawkeOiler, Lubetronic, and Loobman Oiler (manual)).

If you're a starving college student, you can use automotive grease, used motor oil or vaseline in a pinch, and look at the Loobman Oiler.

--------------------------------------------------------------------------------

Adjusting:

Your chain should be checked for adjustment (slack) every time it is cleaned, and anytime you suspect it may be too slack or too tight. The golden rule is that slightly too loose a chain is infinitely safer (and less like to wear prematurely) than slightly too tight a chain. Chain adjustment methods vary between motorcycle models, and we recommend you consult your owner's manual for the proper amount of slack and the method to set the chain tension adjustment by. If you don't have an owner's manual for your motorcycle, we highly recommend you obtain one -- try searching the net, or visit your local dealership to order one. For most motorcycles that use a chain, a total flex of 1" measured halfway between the front and rear sprockets (1/2" up plus 1/2" down) is the ideal. Remember that your chain needs to have some slack so that as it spins up to full speed, it can have room for centrifugal force. The sample adjustment below is for 1998 - 2003 Katanas, as per the owner's manual, as an example:

Replacement:

Your chain will need to be replaced whenever it becomes too elongated, if the rollers are no longer turning freely, and/or whenever your sprockets are starting to wear. It should also be replaced any time you replace your sprockets with new ones, and whenever you see red powder lubricant at the links (see picture "Failure Analysis", above). A typical lifespan for a well maintained chain should be between 8,000 and 15,000 miles (12,500 to 24,000 km). A typical lifespan for a neglected chain can be under 5,000 miles and for an ignored chain is rarely over 2,500 miles. Chains using automated oilers often get 25,000 to 45,000 miles before they need to be replaced, making such oilers a good investment.

tazkat- Moderator

- Posts : 31

Join date : 2010-11-03

:: Mechanical Forum :: How To's

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum|

|

|

Latest images

Latest images